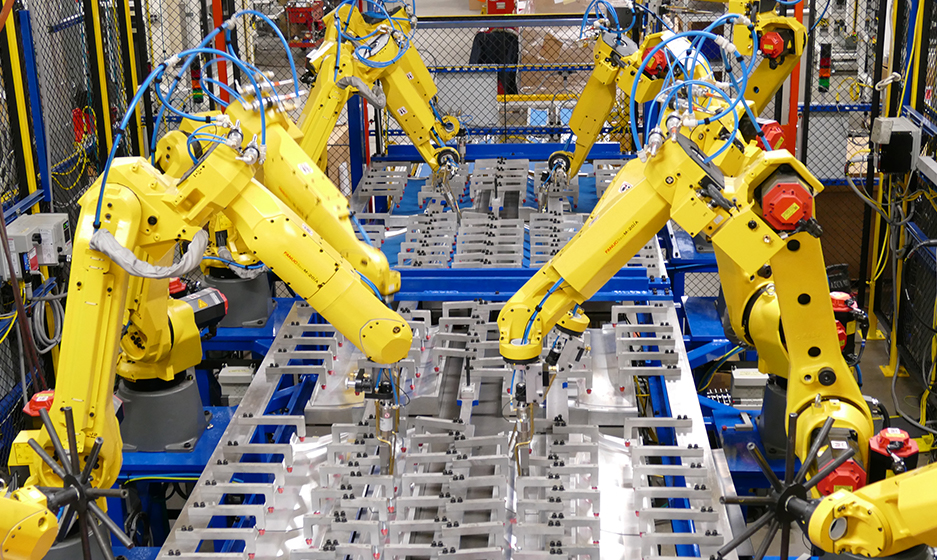

AUTOMATED LINE ASSEMBLY

An automated assembly line

involves using assembly and/or process stations that progressively produce

manufacturers’ end products. These lines may deploy robotics, conveyance,

vision, or other automated technology to complete production tasks in multiple

stations, moving the part or product through each step in an automated

production sequence. Automated assembly lines can take many forms, including

lean automation, flexible automation, and fixed or hard automation.

TYPES OF ASSEMBLY LINE AUTOMATION

FULLY AUTOMATED VS. SEMI-AUTOMATED

LEAN MANUFACTURING AUTOMATION

CONTINUOUS MOTION AUTOMATION - MANUFACTURING

BENEFITS OF AUTOMATING YOUR PRODUCTION LINE

Advantages of automation in your production line include boosting capacity, increasing quality and lowering per-unit production costs, allowing companies to realize higher ROI. Companies that work through applying the right automation related to their product complexity, mix and such can achieve considerable savings in labor costs and repeatable quality. Traditional assembly and processing through only manual labor allows for higher chances of error and product waste; plus, manual labor is reliant on employee attendance to ensure the factory labor source, which is particularly challenging during unplanned situations such as the pandemic. Automation solutions run with limited personnel, reduce error and scrap, and increase productivity, lowering product unit cost and applying more money to the bottom line.